Our strengths

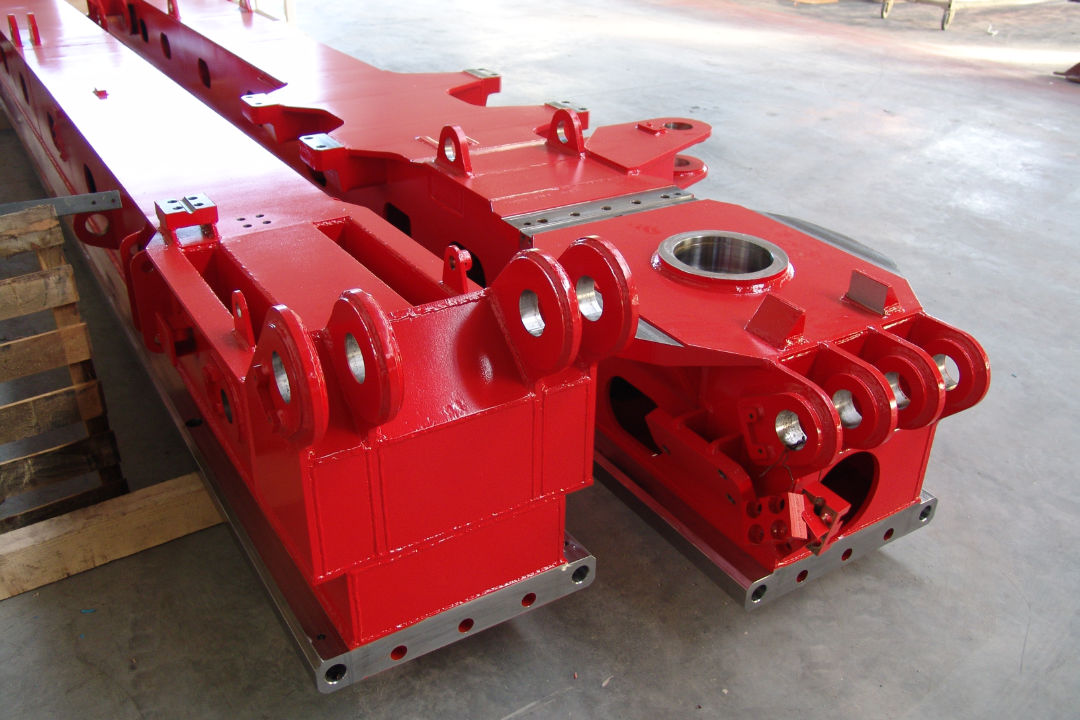

Large parts?

Dimensions up to 20m in length, 4m in width and 3.5m in height are no problem.

Heavy parts?

With our four crane systems we master workpieces up to 25t.

Everything from a single source.

With pre-treatment including blasting, painting and transport from a single source, we offer you comprehensive solutions.

Flexibility

We regard more demanding customer requests as a challenge that we gladly accept.

Easily accessible.

Our location offers an excellent infrastructure. Stetten is well connected to the A7 via the B466 and the L1084. We can also be reached via both roads for special transports.

Partner

For heavier or bulky parts, we offer several forwarding companies as logistics partners with whom we cooperate.

ILE History

Pretreatment

Roller conveyor system

Long workpieces with a width of up to 1500mm and a height of up to 500mm can be accommodated on our roller table system.

Several identical workpieces are blasted there under constant conditions, this process reduces the throughput time and thus also the costs.

Suspension railway system

Larger parts - in terms of height - we can blast in our overhead conveyor.

As with the roller table system, we also achieve high efficiency here through automation.

Flexible and clean blasting allows the plant to produce parts up to 3 tons.

Simultaneously rotating movement also guarantees an optimal surface here.

Phosphating/degreasing

The degreasing/cleaning and phosphating of workpieces, whether large parts by hand using a steam jet or small parts up to 600mm x 600mm fully automatically using a washing system, serves to prepare them for coating.

Due to the recycling of the water, another step has been taken in the direction of the environment.

Jet house

For all other workpieces that - for whatever reason - cannot be blasted on the roller conveyor or on the overhead conveyor, we offer blasting in the blast house as a third option. Due to the size (20m x 4m x 3.5m) and the connection to the crane runway, large and heavy parts can be blasted here. The almost residue-free recovery of the blasting medium enables a quick change of the blasting medium, for example for subsequent fine blasting work such as with corundum or glass beads.

Jet container

Another option for blasting work is our new 40 feet blasting container. With a size of 12m x 4,2m x 4m we can perfectly adapt the application to your needs. By means of a fully automatic blasting medium circuit, blasting material that falls to the ground during the blasting process is fed back into the blasting container in a cleaned state. The consumption of blasting media is thus minimized to the maximum, which not only contributes to environmental protection, but also increases the effectiveness and quality of our work.

Coatings

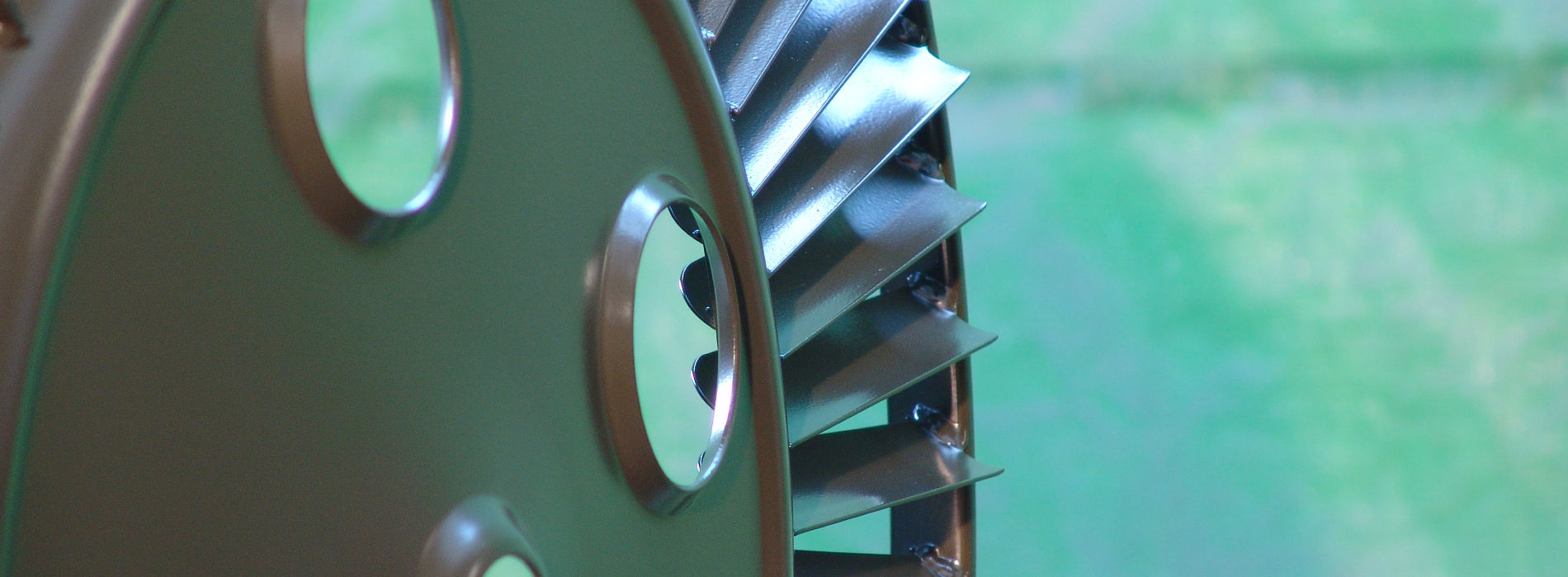

Electrostatic spraying

The electrically charged paint droplets are attracted to grounded workpieces all around - even on the sides facing away from the spray jet. It is often sufficient to paint the workpiece from one side only. This saves time, money and installation effort.

Airless painting

Airless painting is the usual method we use to paint your workpieces.

Airless - cold spray process

Undiluted spray material is atomized at a normal temperature with a pressure of 70 - 525 bar.

Airless - hot spraying

The spray material is heated to 60°C and kept in constant circulation. In this way, highly viscous

material can be processed undiluted and solvents are saved.

Airless - spraying combined with air pressure

Due to the combination of air pressure and hydraulic material pressure, poorly accessible areas can

be varied well.

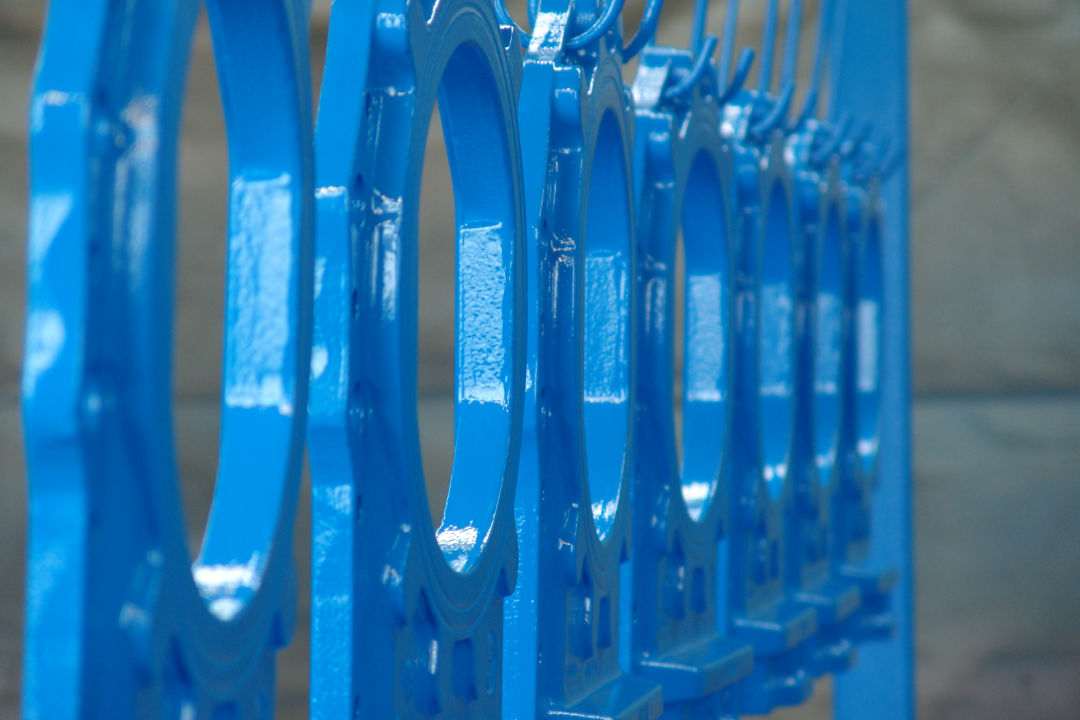

Suspension railway system

With a placement of up to 120 hooks, we are also able to coat small batches economically and quickly.

Incl. drying room

Downstream of the overhead conveyor is a drying room with a temperature of up to 60°C, thus enabling

forced drying of the components.

Ceramic coating

We are also happy to provide workpieces that are constantly exposed to water or other liquids with a ceramic coating that offers a high level of wear protection.

Drinking water approval

This certificate confirms that, on the basis of the certification program DVGW CERT, the product and formulation data provided meet the requirements of the aforementioned assessment basis/guideline of the Federal Environment Agency.

2C technology - Made in Germany

The 2K spray can with your RAL color shade as desired with aerosol technology.

more infoQuality checks

Worldwide recognized Frosio Inspector Level III in house

It is the task of the inspector, on behalf of his customer or his employer, to carry out the inspection and testing of the quality of the workmanship in accordance with the specifications, standards, regulations and material data sheets within the framework of external or internal monitoring. He should detect deviations at an early stage, document them and inform his client or employer of the "defects" he has detected.

Surface roughness Rz, Ra

Beam degree measurement according to SA

Determination of the surface roughness - whether surfaces irradiated with balls or with shot. The

surface profile is compared with the four reference segments of the respective surface comparison disc.

Profiles are recorded in µm.

Bresle Kit - Salt content measurement

To ensure the quality and optimum service life of a coating, it is important to determine the degree of contamination of the surface to be coated before applying it.

If the coating is applied to a poorly prepared, contaminated surface, it can lead to its premature failure and high maintenance costs.

Dust particle test

Used to determine the amount and size of dust particles, on the surfaces prepared for paint coating. Dust adhering to sandblasted surfaces can reduce the adhesion of the coating and result in its premature failure or inferior coating.

Layer thickness control Fe/NE

Dry film thickness is probably the most important measurement in the coatings industry. A coating thickness gauge provides information on the expected service life of the base material, the fitness for purpose of the product and its appearance, and ensures conformity with a wide range of international standards.

Cross-cut test

Adhesion testing after the coating process quantifies the adhesion force between substrate and coating or individual coating layers or the adhesion force of specific substrates. Testing the adhesion strength of coatings not only facilitates the detection of potential coating failure, but also the definition of the physical properties of a coating during its formulation.

Pores testing

High Voltage Testing: High voltage or pore testing can be used to test coatings up to 25mm (1") thick and is ideal for inspecting pipelines and other protective coatings. Coatings on concrete can also be inspected using this technique. The main types of flaws are usually referred to as pores.

Ink film testing - wedge cut method

Measurements on non-metallic substrates or to assess the thickness of multi-layer paint coatings (destructive).

Continuous temperature, humidity and dew point measurement

Painting, if the appropriate climatic conditions are not achieved, can adversely affect the coating and lead to premature defect. Regular measurement - surface temperature of a substrate, the ambient temperature, relative humidity and delta dew point values.

Jobs We are looking to strengthen and expand our team

Industrial painter (f/m/d) - Full-time

Your tasks:- Coating work

- Applications by means of airless spraying

- Surface preparation

- Craft activities

- Completed vocational training in the craft sector is an advantage

- Crane and/or forklift licence advantageous

- Basic knowledge of German or English

- Craftsmanship

- Committed, team player, physically resilient

Sandblaster (f/m/d) - Full-time

Your tasks:- Sandblasting

- Surface preparation

- Craft activities

- Completed vocational training in the craft sector is an advantage

- Crane and/or forklift licence advantageous

- Basic knowledge of German or English

- Craftsmanship

- Committed, team player, physically resilient